Pushing Automotive Design to the Next Level

Find out how Icon Incar uses ProtoPie to take automotive rapid prototyping to the next level.

Meet Icon Incar, the world-leading automotive design consultancy. From their studios in Germany, China and the US, the company takes part in the whole automotive design process by helping their customers:

- Explore automotive mobility and how it changes over time

- Innovate and conduct research through user testing and prototyping

- Execute and deliver the final product

And after having worked with almost every OEM out there on over 100 HMI products and 200 concept showcars, you could say they know a thing or two about bringing car UX design ideas to the streets.

Just check out the interfaces on the BMW iDrive below.

But, the team at Icon Incar also learned one thing: without the right UX design tool in your tech stack, automotive prototyping can be both ineffective and hazardous.

Luckily for Icon Incar, they found ProtoPie.

We spoke to Dennis, Associate UX Director at Icon Incar, and Daniel, Creative Technologist at sister company Icon Impact, to hear how ProtoPie has transformed their automotive design process.

Why prototyping is important for Icon Incar

“In the beginning, it was mainly about static design and creating these perfect images of what we wanted to put in a car or a web app,” Dennis says.

While prototyping wasn’t a big part of that in the beginning, he tells us that Icon Incar realized over the years that creating prototypes improved the overall design process.

Automotive systems are really complex, and can take a lot of time to design. To put it into perspective, a single automotive design project can take up to 4-5 years to complete.

Obviously, you don’t want your vehicle to fail while driving at high speeds on the autobahn. So, in the automotive space, you need to make sure that everything works perfectly to avoid accidents.

That’s why it is really important for Icon Incar to create really good working designs.

And the longer you work on a project without prototyping, the less efficient you get over time because just creating the aesthetic images asks for a high abstraction level on the client side.

Abstract designs make it hard to explain your ideas to the client in a clear way.

That leads to misunderstandings and many unnecessary iterations, slowing down the overall automotive design process.

On the other hand, prototyping changes the game completely. Let’s see exactly how.

How prototyping helps Icon Incar improve their design workflow

Right now, there are three main pillars where Icon Incar uses prototyping:

1. Create and Validate: Design and test which future works best

Icon Incar’s first pillar is to use prototypes in visual design to create smart solutions to big problems. This is followed by user testing to evaluate if the designs work as expected.

2. Present: Communicate tomorrow’s ideas today

The second pillar is super important from an agency’s perspective.

As mentioned earlier, Icon Incar struggled with the high abstraction level of their previous design processes. Using ProtoPie for high-fidelity prototyping gives them a communication tool to express exactly how their ideas will look in the final product.

3. Handoff: Take the idea to the streets

As Icon Incar is heavily involved in the production side, prototyping helps their designers and developers speak the same language. That means they can have their designs carried out in the final product, and really take their ideas to the streets and to the users.

By leveraging design communication in automotive design, prototyping makes it easier to:

- Reduce the abstraction level and therefore enhance the decision-making process.

- Through better and faster decision-making, they can deliver a better quality of design artifacts with less reworks.

- Finally, this leads to a faster time-to-market ratio and more time to design product evolution instead of reworking current design decisions.

How ProtoPie supports Icon Incar in different implementation levels

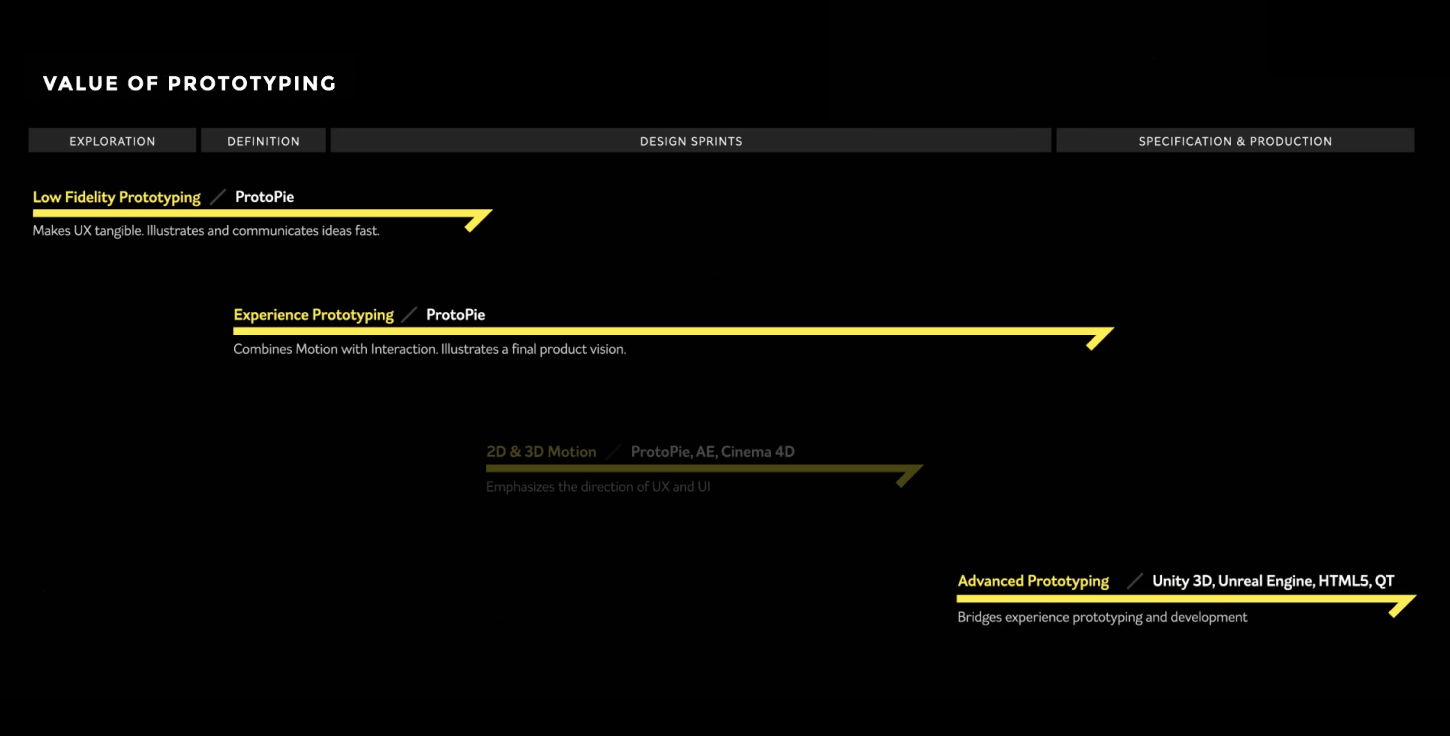

So, how does prototyping make the whole process more effective? Say that we have four phases, like:

- Exploration

- Definition

- Design Sprints

- Specification & Production

Then, different categories of prototypes help the company throughout the entire design process.

“At Icon Incar and Impact, we define some categories of prototyping that we are using in our day-to-day business,” Daniel explains.

First of all, there is the low-fidelity prototype. The only use case is to make the UX tangible, illustrate, and communicate ideas quickly.

The next one is experience prototyping, which uses motion and interaction to show what the final product will look like. At this stage, Icon Incar wants to simulate the end experience–how it will look and feel to interact with the product. With ProtoPie, they can easily import their motions from After Effects into ProtoPie.

Then there is advanced prototyping, which will happen on the target technology or target device most of the time. The benefit is that developers can reuse the code base using ProtoPie’s handoff features.

ProtoPie’s versatile features make it possible for Icon Incar to use it throughout the entire automotive design process, from the exploration phase to the specification phase.

Examples from Icon Incar: ProtoPie Automotive Design

So, how does it really work? Let’s find out through two real-life product examples that show how Icon Incar implements ProtoPie in their automotive design workflow.

1. Future control of HVAC systems

Using AI, Icon Incar created a prototype for an in-car HVAC (heating, ventilation and air conditioning control) system. The AI system sets up the climate inside the car based on factors like:

- Traffic

- Outside temperature

- Driver stress level

But if the driver prefers custom settings, they can override the settings to make their own modifications. The AI system learns from it.

Here is how it looks like in low-fidelity prototyping.

The prototype is straightforward and simple, only showing concepts. This has some benefits, especially because it allows you to quickly test whether different design directions will work.

But what about when it is a high-fidelity prototype?

Motion comes together with more detail interaction patterns and design. You can interact with the prototype in real time, testing patterns like changing the temperature in the car or snapping behavior.

If you are doing experience prototyping, your project can become very big, very fast. Especially if you do a whole HMI system in ProtoPie, and in that case, you may find these tips useful:

- Use the power of events: Events are a game-changer for cross-component communication, making it possible to scale the whole prototype.

- Think in delegate patterns: Delegate patterns make it possible to sub-classify your prototype where each component has its own task.

- Create symbols and override your instances: Your best friend for big projects, as you just have to edit the master file to change all instances automatically.

- Build your library with tools: For example, by creating a timer component into a library file means you can drag and drop it to each project and nothing changes because it will always work the same. No need to create a new timer for every new prototype or project.

Of course, experience prototyping is not all about software. It is also about getting in touch with hardware prototyping, which brings us to the next example.

2. Creating a versatile seating buck

You may remember one of our latest pieces on electric car prototypes made with ProtoPie.

These days, a lot of OEMs and companies are also trying to figure out what the experience of robot cars will look like in the future.

Icon Icar experienced that obstacle firsthand when they worked on a future robo-taxi service with one of their clients.

There are a lot of questions involved, such as:

- How do I enter the vehicle when there is nobody in there?

- How does the vehicle see me when it is approaching my destination?

- What are the future revenue streams?

How did they approach the problem? With a well laid out testing strategy, and capable seating buck.

And, well, with ProtoPie Connect.

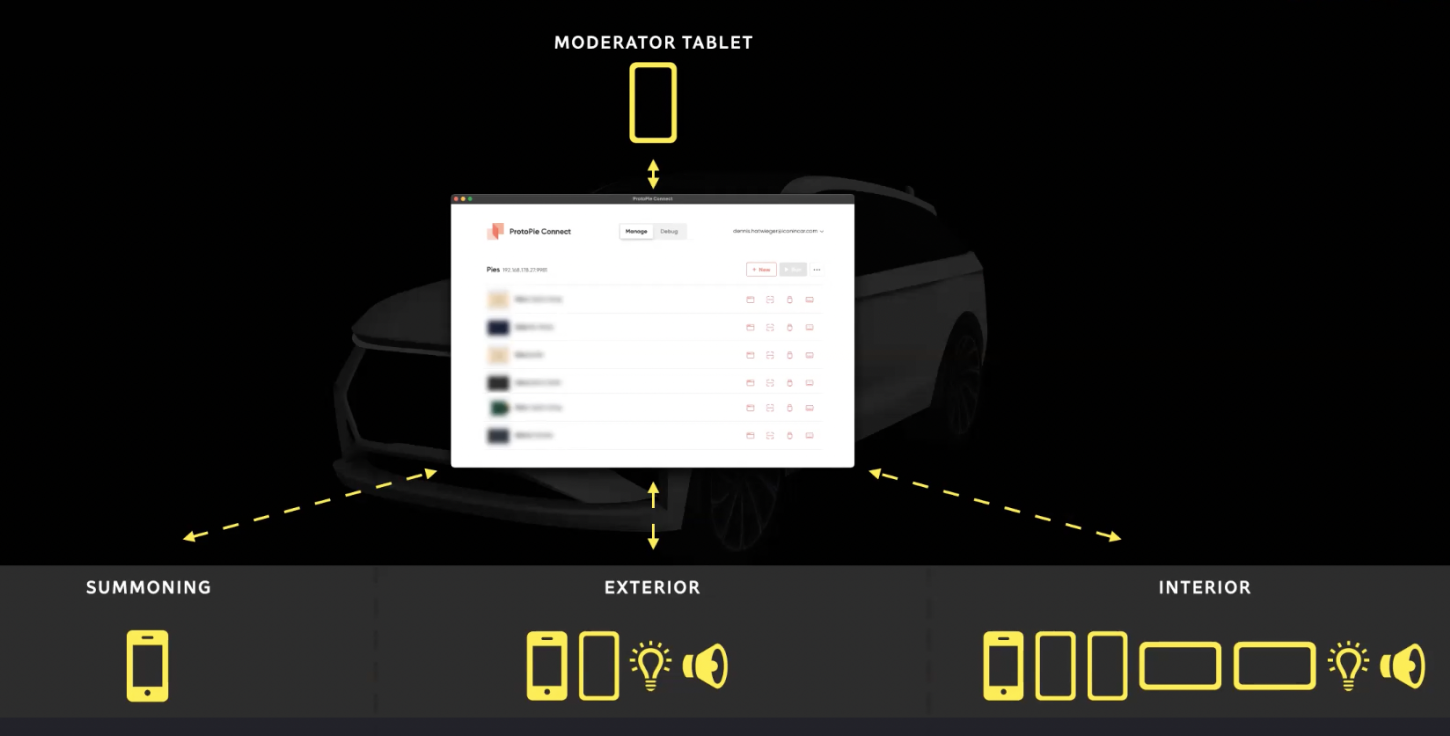

In the end, they had about 12-13 devices connected to one seating buck at a time. Including a smartphone, multiple exterior displays, lights, sound systems and interior screens.

The great part about ProtoPie Connect was that it took over the communication between all those devices. That meant they could gain valuable insights in the automotive design validation process about how to shape the end product.

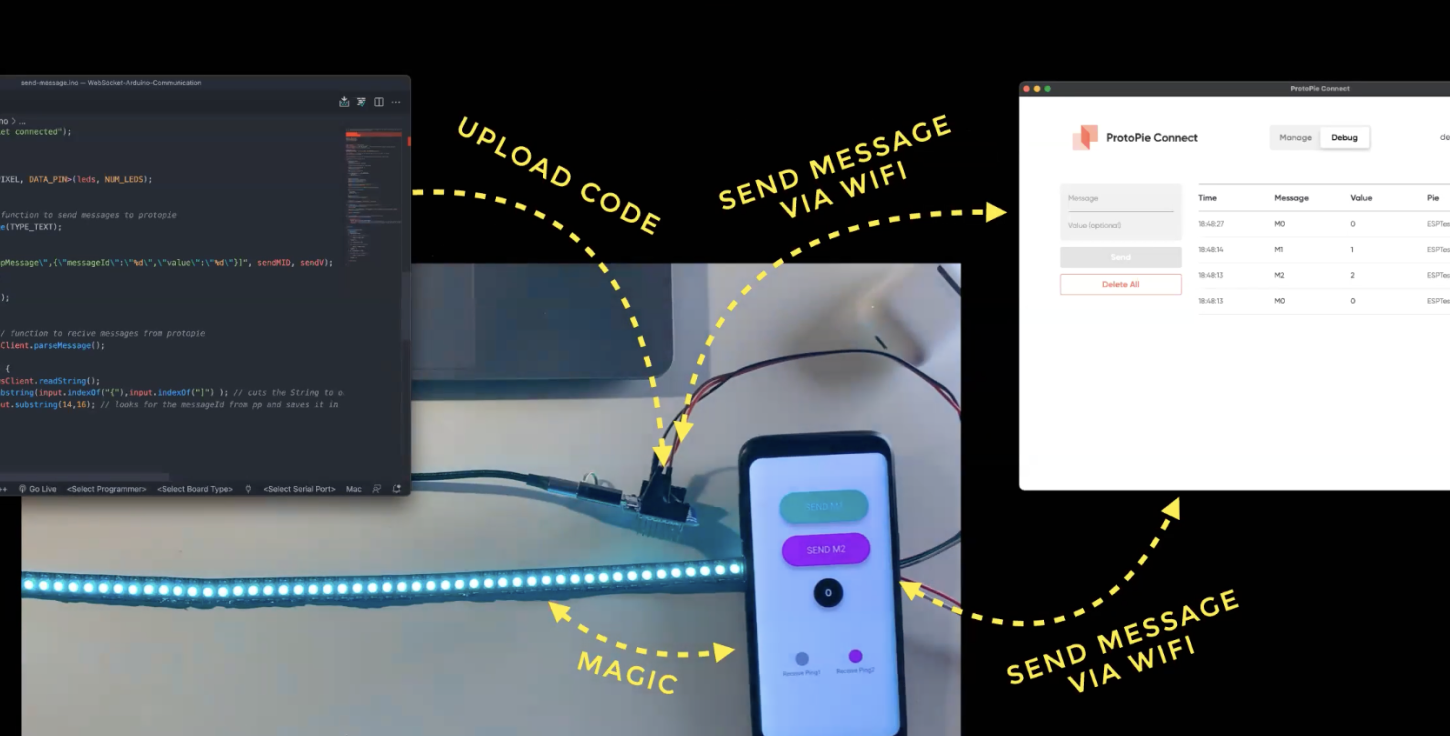

They also took advantage of coding resources on Github, which they could easily apply to their prototype.

Before, it was hard to exchange prototypes during user testing. With ProtoPie Connect, that can be done in a matter of minutes.

What’s more, you can see how easy it is to get your sensors and actuators communicating with your smart phones and other devices that make up part of your digital experience.

Bring your automotive prototypes to the streets with ProtoPie

ProtoPie is the go-to prototyping tool for Icon Incar and thousands of other companies, helping them bring their abstract ideas to life.

Book a demo today to figure out how we can help you succeed.