Prototyping for Automotive HMI : Designers in the Driver's Seat

Learn from ProtoPie's CEO, Tony Kim, how designers can take the lead in automotive prototyping.

Prototypes are invaluable tools in a designer’s arsenal. When made well, they let you express your innovative ideas and convince stakeholders that your product is feasible.

But, since automotive prototyping for human-machine interaction (HMI) can be complex, designers in the field have long taken a backseat to developers and engineers.

With ProtoPie, those days are gone.

Why designers should build automotive prototypes

Tom Kelley, an IDEO partner, once said that “if a picture is worth 1000 words, a prototype is worth 1000 meetings.”

This is one statement I truly believe in.

When validating product ideas, you need more than back-to-back meetings with static UX designs and complex tech jargon that help little in bringing ideas to life.

It’s clear that when designers are in the front seat of prototyping, companies are better off. Here’s why.

1. Save time and money

Prototyping helps you communicate your design ideas before you implement them. When you know what works and what doesn’t in the pre-implementation stage, it saves your team and company engineering resources and time.

2. Avoid making wrong assumptions

With prototyping, you can explore and validate many design possibilities. As designers, we may sometimes lose direction and need more confidence before bringing our ideas to the team. Prototypes help us convince both ourselves and others that our ideas have merit.

3. Give end-users the real experience

Prototyping is the most cost-effective way to get feedback from real target users. So many product launches have failed because they didn’t accurately predict what people wanted. To ensure your product’s success, you need feedback - which means the users need to try the real thing.

Yet despite these benefits, designers in the automotive industry struggle to build high-fidelity prototypes.

Often, automotive designers rely on unrealistic click-through prototypes or leave the prototyping to developers.

But, that doesn’t have to be the case.

Watch the following video about Prototyping for Automotive HMI to learn more.

HMI is more complex - and so is prototyping

Well, you may ask - aren’t today’s digital products more complex? Yes, they are! Especially in terms of HMI.

There are three factors that explain why digital prototyping has become increasingly more complex in recent years. Let’s look at each one.

1. Connected devices

Human-machine interactions are far from linear. Today, people interact with multiple machines that are interconnected to each other.

The number of IoT-connected devices installed worldwide has more than doubled in the past 7 years. Statistics predict that by 2025, the average person will have nine connected devices - including smartphones, wearables, smart meters, and other machines.

2. Hardware-software integrations

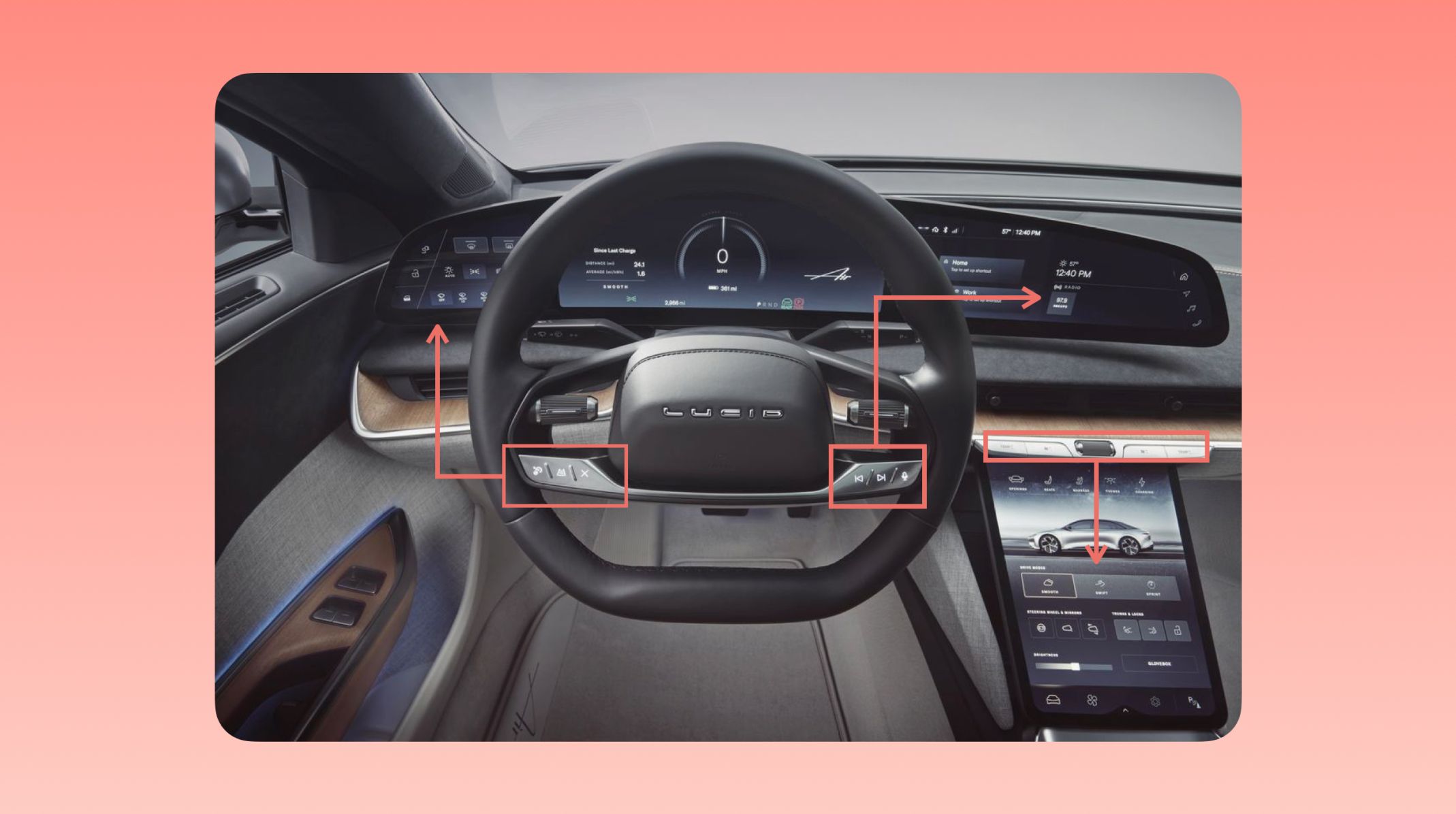

Have you heard of the Lucid Air car? It’s a great example of how the integration of HMI software and hardware in-car UX has made the prototyping process a little more complicated.

The car has four HMI displays in the driving seat and several physical buttons on the steering wheel.

All of these components communicate with each other for a seamless user experience.

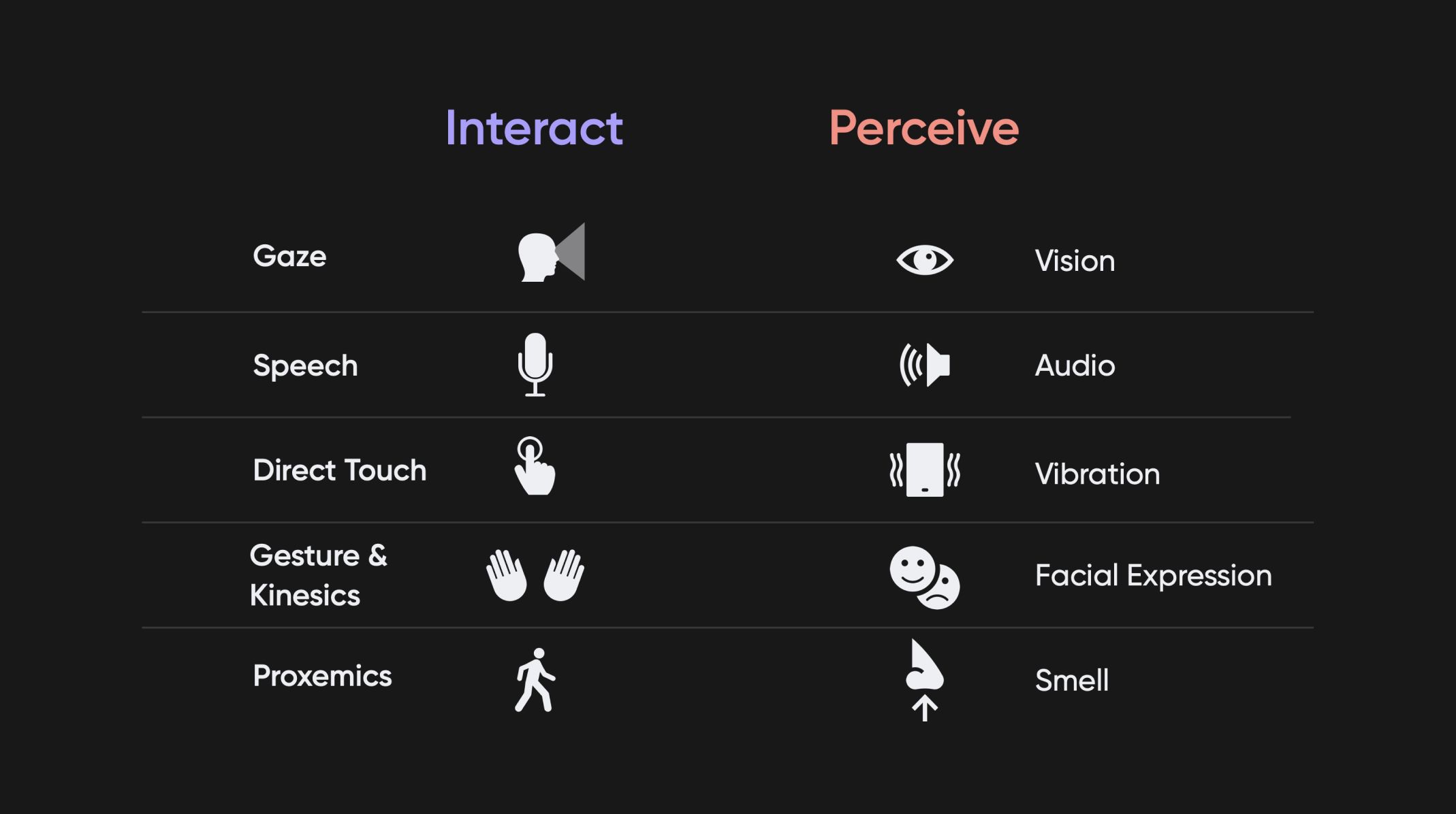

3. Multi-modality

Modern HMI offers multi-modality, which means you can use not only touch screens, but also voice commands and hand gestures. Some luxury vehicles support haptic feedback upon users’ inputs or sensor signals.

For example, the all-new BMW 3 series includes an intelligent AI assistant that supports both voice commands and hand gestures.

These new features are great for the user - not so great for the non-tech-enabled automotive UX designer.

As a result:

- 8 out of 10 designers in the industry found high-fidelity prototyping “very hard.”

- Most designers are heavily dependent on engineers.

So, that leaves the question - how can we make automotive UX for HMI software easier for designers?

High-fidelity automotive prototyping does not have to be complicated

So far, I have established that human-machine interactions, especially in the automotive industry, are a lot more complex today.

But, prototyping these does not have to be complicated.

That is where ProtoPie comes in.

Let’s see some examples of prototypes made with ProtoPie.

- With our voice prototyping feature you can have real voice interactions with any HMI. Execute voice commands and let them be spoken out loud. Moreover, ProtoPie supports 52 languages and dialects thanks to a collaboration with the Google Assistant UX team. You can build voice commands in your mother tongue. Make realistic prototypes for accessibility, voice search, voice assistants, dictation apps, and so much more.

2. The design team at Arrival built a prototype that is designed exactly like the real end product. They test the prototypes using a simulator with a real engine, pedals, steering wheel and a screen on the right-hand side. The simulator and the prototype allows them to look into the ergonomics of how people physically interact with the screen while looking down the road and driving.

Beyond that, they can also observe what physical controllers do and how it looks on the screen interface. For instance, hitting stop on the gearbox (stopping the car), steering the wheel, pressing the gas pedal, etc.

Being able to test out these interactions allows them to get quick feedback and new iterations as necessary—even as early as the next day.

3. Real car integration is also possible with ProtoPie Connect. You can receive a wide range of real car diagnostics, such as speed, tire pressure, AC temperature, and fuel level, via the OBD port. This will allow you to receive and process real-time data instantly and build prototypes accordingly. In this demo, for instance, signals are received through the OBD2 port, showing the speedometer, RPM gauge, gas gauge in the dashboard prototype.

4. ProtoPie allows integration with any custom hardware, not only for automotive. You can design and test out home appliance knobs without a single line of code using Arduino. The following demo was made for Bosch: Turning the physical knobs will make the dials on the screen rotate accordingly.

Learn more about our Arduino plugin.

5. This demo made for Piki Burger shows how multiple devices can communicate with each other. The following is a simple version of a kiosk mobile payment system. Start from choosing your meal, adding extra options and selecting the method of payment. Continue to complete the payment with your phone application just by tapping the back of your phone to the Kiosk tag. More real, impossible!

Design multilateral automotive HMI experiences without engineers

Let’s recap:

- Prototyping is an extremely valuable process that both can and should be led by designers in the front seat.

- With methods based on human language, we can find more intuitive ways to prototype.

- The intuitive way should be scalable to adapt to complex and high-fidelity prototyping.

- In this way, designers can prototype multilateral HMI experience without the support of engineers.

Book a demo today to discover how ProtoPie makes this possible!